We began with getting and idea of our fields and what we are all interested in doing. As you can see above, our team is very balanced, and everyone is interested in doing very different but symbiotically beneficial parts of the project (I myself will basically be doing a bit of everything ^^).

Jordyn - Project Manager, Mechanical system, servo configuration

Casey - Mechanical

Lisa- Freelancer, coding :), mechanical, help with website, documenting

Noura - GUI, image processing, website.

In terms of team dynamics, things are looking very good.

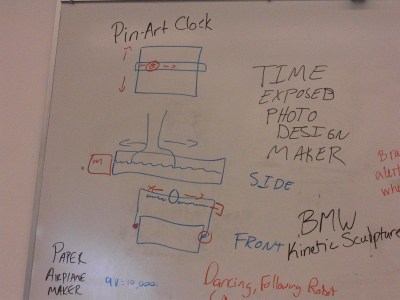

While the rest of us were getting into setting up the scope of our project for our project proposal (due march 2), Casey already started looking into ideas for how our project might look like and stumbled upon this:

http://www.engadget.com/2011/07/30/cnc-mod-carves-dot-drawing-portraits-for-your-living-room-walls/

From there we began breaking our project into pieces and getting a general idea of how to do things and when things would be due. (i'll post later how we ended up breaking our project. This part includes things like minimum deliverables, wood or foam, etc). There are approximately 9 weeks (ignoring spring break) till our final demonstration, along with two other design reviews in between, which actually doesn't really give us much time. We all agreed that it would be good to set up an accountable meeting, which would make scheduling much easier for the future (specially when two of us have UOCD...Note for all those who are intending to do group projects in the future. This is very important to do because setting up meetings every week on the go makes things even harder to try and find syncable meeting times... This will make it so that you are scheduling around the team meeting instead of scheduling your team meetings around all your other meetings). Jordyn sent an ical for Thursdays from 7-8pm.

For Team contacting and work syncing, we set up a google doc (which also had our project proposal on it) and input our contact info. Noura also set up a "text everyone" number for easy group contact.

https://docs.google.com/document/d/1wOPgAupNXiIk6mKCY9MZrfFBy4lRZtsw8i3mLezHwSQ/edit?pli=1

Noteable sites:

http://www.ehow.com/video_8000414_using-end-mills-wood-lathes.html

For Poe Day 2:

Each of us need to do some brainstorming and research for parts, budget, implementation methods, and other necessary components by Tuesday. Hopefully we would then finish our project proposal in class that day. (whoo hoooo, get ahead schedule! Our general plan is the have a more minimum deliverable done early then with thee extra time, refine it and add to our ... machine). I think i'll be looking up GUI things, how to make website, and some basic implementation methods (a little into the mech E side).